In this article, you'll discover:

- The different types of warehouse roofing systems and their key features.

- Pros and cons of metal, modified bitumen, built-up, single-ply, and liquid-applied roofs.

- Critical factors to consider when selecting the right roof for your warehouse.

- Tips for ensuring long-term durability and protection of your warehouse roof.

We get it, talking about warehouse roofing isn’t the most glamorous topic in the world. Well, it’s not quite exciting, until... your roof is leaking all over your inventory.

So, let’s nip this is the bud before it happens and explore how to identify the best roofing system for your warehouse. Companies need to be prepared to make informed decisions when it comes to how their needs influence their optimal industrial roof.

Because not only does the roof safeguard your inventory but it should provide critical protection for your team members. This is even more important with the number of accidents on the rise. For instance, in 2021, a construction worker fell through the roof of an Amazon industrial facility.

You can’t risk making mistakes, so we’ll go through the types of roofs available on the market today, their advantages and disadvantages, as well as important tips for choosing the right one for your needs in a facility. For corporate tenants, this is critical information in the property search. Read on to learn more about how you can select a suitable roof for your warehouse!

Types of Warehouse Roofing

There are many factors that must be taken into consideration. From watertightness and energy efficiency to maintenance and appearance, all these aspects should be addressed before making an investment in new roofing. Your roofing material will first depend on the type of roof you have. For example, flat roofs demand the appropriate drainage systems while pitched roofs are designed to shed water.

Metal Roofs

Metal roofs are a popular option for warehouses due to their endurance, energy efficiency and low cost. With the appropriate safeguards, metal roofs can last anywhere from 40-80 years, making them the most time-enduring roofing. Metal roofing is usually applied on sloped or pitched roofs.

There are three types of metal roofing:

- Steel

- Aluminum

- Zinc

Most metal roofs are made of steel, and for practical reasons. Not only are they durable, but reasonably priced. As an added layer of protection, the steel is typically coated with aluminum or zinc. This will enforce corrosion resistance and reflectivity.

Aluminum metal roofing is lightweight and easy to work with, but is more expensive than steel. It is highly resistant to corrosion and rust, making it an ideal choice for areas prone to extreme weather conditions.

Zinc roofs are an excellent choice for areas at high-risk of exposure. Zinc is a corrosion-resistant material that has been used in construction since the 16th century, so it is highly reliable and can last for decades with proper maintenance. In addition to their superior corrosion resistance, zinc roofs also offer excellent energy efficiency and reflectivity, reducing cooling costs in the summer.

Metal Roof Styles

Metal roofs come in a variety of styles to meet the needs of any project.

Exposed-fastener systems are the most affordable and associated with simple installation. Although, they are commonly used for residential applications, these roofing systems feature metal panels with pre-drilled holes that attach directly to the roof’s structural frame.

Concealed-fastener systems offer aesthetics. If roof structures are visible, it will likely be this type of style. Panels are interlocked together with hidden clips and sealed at each joint using specialized tools. These roofs are more expensive and require specialized installation, but they offer superior performance and longer life expectancy.

Metal roofs are generally constructed with either a low or steep-slope pitch in order to ensure adequate drainage. While metal roofing may yield a more substantial upfront cost, it is a reliable and durable roofing solution. Metal roofs are known for their longevity, with some manufacturers offering warranties of up to 50 years. However, metal roofs require more skill and expertise when it comes to installation and maintenance compared to other roof types.

Modified Bitumen Roofs

Modified bitumen is an increasingly popular type of roofing system for warehouses. It is a reinforced asphalt membrane blended with plastic or rubber polymers to improve its malleability, making it more durable than traditional asphalt roofing.

The modified bitumen roofing system can be made into smooth or granulated rolls. Granulated rolls typically provide more impressive UV protection and increased staying power. Additionally, this type of roofing is highly resistant to water intrusion and is relatively low maintenance, requiring only periodic cleaning. Modified bitumen roofing also offers good energy efficiency, helping to keep warehouse temperatures consistent and lower energy costs over time.

Modified bitumen roofing for warehouses is typically more expensive than other traditional roofing materials. This higher cost is due to the quality of materials used and the extra labor involved in its installation, which usually demands special equipment and advanced skills, making it a much pricier option than other common alternatives like asphalt shingles or metal roofing.

However, despite the initial cost, the long-term savings in energy costs and maintenance make it a worthwhile investment for many warehouse owners. Additionally, modified bitumen roofs can often last up to 25 years or more with proper maintenance, making them an economical option in the long run.

Built-Up Roofs

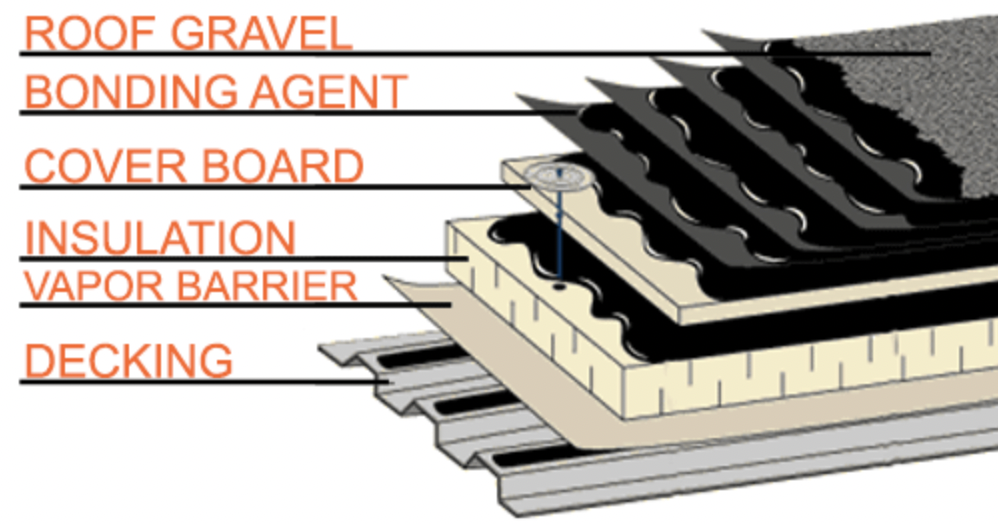

Built-Up Roofs (BUR), also known as tar and gravel roofing, have been around for centuries, providing reliable protection to many commercial buildings. BUR consists of several layers of asphalt or bitumen, which are reinforced with a layer of reinforcing fabric and then covered with gravel, slate or other protective material. These multiple layers make them an incredibly durable and watertight roofing system for warehouses.

They are also relatively low maintenance, since they can be easily repaired with patching material or extra layers of gravel, if needed. Another great advantage is that they are highly resistant to UV radiation and strong winds, making them a great choice for coastal areas or in places where wind speeds can be high. One of the major drawbacks of this type of roofing is that they are more expensive than other systems, as well as heavier and more difficult to install.

Finally, BUR systems require periodic inspections and maintenance in order to keep them functioning properly and safely. This includes removing any debris that may accumulate on the roof, checking for signs of wear or damage, and replacing any damaged components. Regular maintenance can help extend the lifespan of your BUR roofing system, saving you money in the long run.

In the end, the lifespan may make the headaches worth it, coming in at an average 50 year lifespan.

Single-Ply Warehouse Roofs

Single-Ply Warehouse Roofs are a great option for those looking for an affordable and low-maintenance roofing system. These roofs consist of a single layer of synthetic material that is applied directly over the existing roofing structure, providing an extra layer of protection against water and other elements. This type of roofing is also much lighter than other alternatives, making it easier and faster to install.

Image Source: Roberts Roofing

Single-ply roofs are highly resistant to UV radiation, wind and mildew, making them an ideal choice for warehouses in all climates. Additionally, they require little or no maintenance as they are self-sealing and can be easily patched if needed.

There are three types of single-ply roofs:

- TPO

- PVC

- EPDM

TPO is a relatively newer technology with a life expectancy of 10-25 years, while PVC looks almost identical to TPO but lasts for 15-30 years. Finally, EPDM, which is often referred to as “the original” single-ply roofing membrane, can last up to 40 years.

Single-ply roofing is an increasingly popular option for warehouses due to its ease of installation and cost-effectiveness. However, there are some drawbacks to single-ply roofing that should be considered before making the investment.

Image Source: Weather Bond Roofing

Single-ply roofing may lack the durability of other more robust roofing systems, but it can still provide reliable protection if installed correctly. Since it is a single-layer membrane, it is at a far greater risk for sudden damage and requires special equipment and advanced skills for proper installation. Additionally, these roofs rely heavily on seams that must be correctly sealed in order to prevent leaks. Proper care and maintenance should be taken to ensure that the roof is not compromised. While it is a practical option for many commercial buildings, it may not be the most suitable choice for longevity.

Liquid Applied Roofing

Liquid applied roofing is a type of warehouse roof that is typically made of rubberized asphalt and other waterproof coatings. This system provides an economical and sleek look to any building, while also offering superior protection against water, fire, and wind damage.

Image Source: MBM Roofing

Unlike traditional single-ply or metal roofs, liquid applied roofs require an experienced and certified professional to install, as they involve the application of materials by hand. The process involves spraying a mixture of rubberized asphalt and other waterproof coatings onto the roof in order to create a seamless membrane that provides superior protection against environmental risks.

Liquid applied roofs can last for up to 15 years with the option to re-spray the finish. The cost is usually about half of what’s expected for the other roof types.

Finding the Right Warehouse Roof

When it comes to choosing a warehouse for your business, there are obviously many things you need to take into consideration. To be honest, the roof is only the tip of the iceberg. From flooring and racking systems to dock doors and HVAC the list can seem endless. So, don't lose track. Learn the 70+ points you need to consider to find your optimal warehouse.

The True Tenant Reps™ at iOptimize Realty® are experts in identifying and conducting due diligence for optimal warehouse properties. We have 30+ years of experience finding the best warehouses for the best price. Now, we want to share the tips and tricks we've developed to empower corporate tenants. We poured our industrial real estate due diligence into the free course below.